In my kitchen at home we use cooking pots and pans made from a variety of metals, and I thought it would be an interesting project to delve into the pros and cons of each material and then go on to see how that works with refrigerator evaporators.

In my kitchen at home we use cooking pots and pans made from a variety of metals, and I thought it would be an interesting project to delve into the pros and cons of each material and then go on to see how that works with refrigerator evaporators.

After all, cooking pots and fridge evaporators both utilize metal surfaces to transfer heat, so many similarities exist.

When cooking on the stove, we're conducting heat from an external source (the burners), through the material of the pot or pan to the contents in the interior.

Simple enough you'd think, but different metals have different characteristics, and work in different ways. The ability of a material to transfer heat is known as its Thermal Conductivity. This is quoted in various units, but here we'll use good old fashioned BTU's per hour per foot per degree Fahrenheit (Btu/hr-ft-F).

Listed below are some of the common metals used for cooking pots and pans together with their Thermal Conductivity rating, starting with the most conductive and ending with the least. Basically, the higher the number, the more heat the material will conduct through it

Phone: (301) 352-5738

Email: info@CoastalClimateControl.com

Office | Warehouse:

1598 Whitehall Road, Suite D

Annapolis, Maryland 21409

There has long been a debate about air cooling versus water cooling for marine refrigeration systems. Water cooling has traditionally been generally accepted to be between 25% and 35% more efficient in warm/hot ambient conditions, but some of that efficiency gain has to be offset by the energy required to run a water pump.

There has long been a debate about air cooling versus water cooling for marine refrigeration systems. Water cooling has traditionally been generally accepted to be between 25% and 35% more efficient in warm/hot ambient conditions, but some of that efficiency gain has to be offset by the energy required to run a water pump.  Inner Secrets of the

Inner Secrets of the

Are you, or is anyone you know, a Temperature Control Freak? You know the type; constantly fiddling with air conditioning and refrigerator controls and reporting on them to anyone within earshot. Well, I have such a friend.

Are you, or is anyone you know, a Temperature Control Freak? You know the type; constantly fiddling with air conditioning and refrigerator controls and reporting on them to anyone within earshot. Well, I have such a friend. We handle many calls for troubleshooting help, and the vast majority end up being electric problems, mostly with the boat’s power supply to the Frigoboat unit. While the voltmeter on the distribution panel might show more than adequate power, it is what comes out of the end of the two wires at the Frigoboat unit that counts, and there is a lot of potential in the wiring for gremlins to creep in and spoil the party.

We handle many calls for troubleshooting help, and the vast majority end up being electric problems, mostly with the boat’s power supply to the Frigoboat unit. While the voltmeter on the distribution panel might show more than adequate power, it is what comes out of the end of the two wires at the Frigoboat unit that counts, and there is a lot of potential in the wiring for gremlins to creep in and spoil the party. Remember back when you had to defrost your home refrigerator every couple of weeks? It was a fact of life. And then those frost-free refrigerators came about. No more defrosting!!

Remember back when you had to defrost your home refrigerator every couple of weeks? It was a fact of life. And then those frost-free refrigerators came about. No more defrosting!! Anyone with a refrigeration system on their boat or RV that is powered by a Danfoss (now Secop) BD35 or BD 50 compressor should be aware of the diagnostic diode function, which, with a simple flashing LED, tells you the fault reason that caused your compressor to stop. Much of the following also applies to the BD80 compressor controller.

Anyone with a refrigeration system on their boat or RV that is powered by a Danfoss (now Secop) BD35 or BD 50 compressor should be aware of the diagnostic diode function, which, with a simple flashing LED, tells you the fault reason that caused your compressor to stop. Much of the following also applies to the BD80 compressor controller.

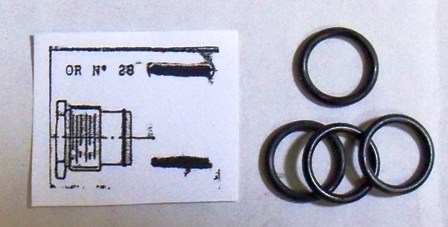

The couplings used on Frigoboat component refrigeration systems are proprietary to Frigoboat and are designed for long and trouble-free service. Some time ago it was noticed that there was an increase in reports of leaking

The couplings used on Frigoboat component refrigeration systems are proprietary to Frigoboat and are designed for long and trouble-free service. Some time ago it was noticed that there was an increase in reports of leaking

It’s a boat. Something’s going to break, and if you’re in the middle of the ocean or in a deserted anchorage in Paradise, who’s going to fix it? There’s no handy-dandy repair chappie down the road, and no one to beg come and mend it, so if you don’t fix it, it stays broke. Simple.

It’s a boat. Something’s going to break, and if you’re in the middle of the ocean or in a deserted anchorage in Paradise, who’s going to fix it? There’s no handy-dandy repair chappie down the road, and no one to beg come and mend it, so if you don’t fix it, it stays broke. Simple.

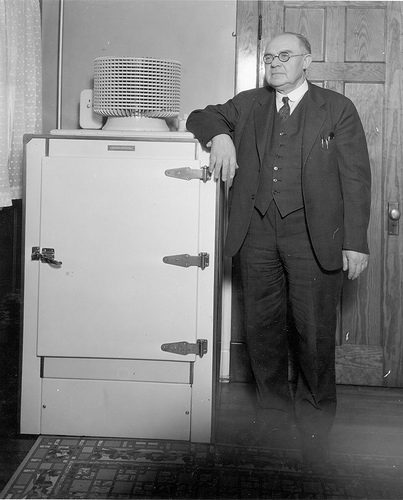

Once upon a time, a long time ago, there was only one brand of refrigerator that would work on 12v DC boat power. There must have been many thousands of them out there back in the day, predominately on powerboats, and a lot still exist to this day.

Once upon a time, a long time ago, there was only one brand of refrigerator that would work on 12v DC boat power. There must have been many thousands of them out there back in the day, predominately on powerboats, and a lot still exist to this day.